Click above to watch the video

Get the Ortur Laser Master 3 for $30 off with code “TOMMY30” at checkout

I’ve been learning about and using the Ortur Laser Master 3, and laser engraving in general, for about the last week and I’ve been able to create a few different projects with it. I knew nothing about laser engravers a week ago and I have nothing to compare this particular laser too, so keep that in mind.

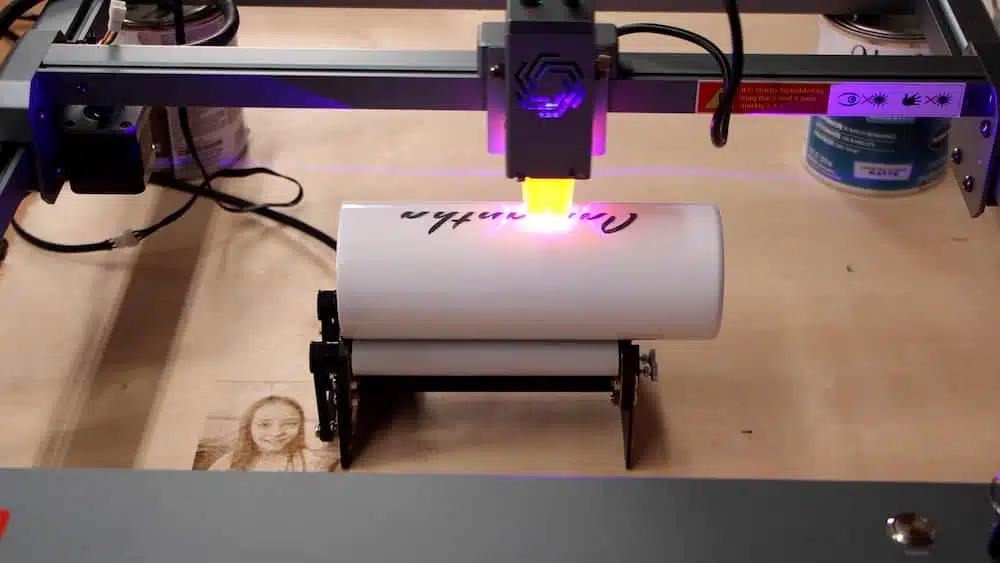

This laser was sent to me by Sinis (sinismall.com) and they were kind enough to include the Ortur rotary attachment for engraving cups, glasses, and mugs.

Spending time with the Laser Master 3 was an enjoyable experience. It’s a solid machine that didn’t give me any issues. It was easy to put together and the action is smooth and stable.

Diode Lasers

This is a diode laser that focuses the diode beams with mirrors and lenses to a fine point. The laser has to be set to a specific distance from the material you’re working on so that the fine point is focused right at the surface.

On the Laser Master 3 this is done with an included kickstand that folds down so you can drop the laser to the correct height and then fold the kickstand back up. No need for separate spacer blocks.

Diode lasers are the weakest of the most common types of lasers (Diode, CO2, Fiber). But, they are still more than adequate for a hobbyist or even small business owner wanting to create some projects that require precise cutting and carving.

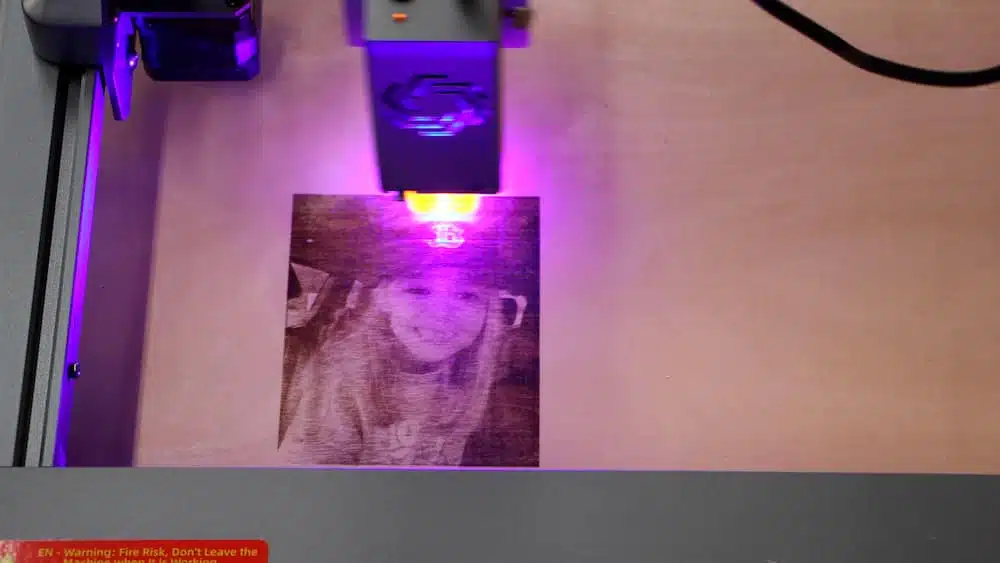

The Laser Master 3 is accurate and the resolution is really impressive. I still find myself marveling at the ability of this thing to carve in such tight places.

Diode lasers are also the most affordable and are more accessible to the hobby market, although they are still pretty pricey. You can get this 10W laser with a 400 mm by 400 mm (15.75 in x 15.75 in) cutting capacity for around $600. The rotary attachment is well under $100, at the time of writing.

I didn’t have any trouble with the projects I was trying to create with this laser. It easily engraved these coated tumblers and cut out 1/8″ balsa wood in one pass, at about 50% power.

If you have aspirations of creating a business that sells products you make with the laser (either online, or at a farmer’s or craft market), you could conceivably start out with a diode laser like this. But, eventually, if you want to scale to any meaningful level of production, you’ll probably want to upgrade to a faster CO2 laser.

Should a Woodworker Get a Laser?

So, with all of that said, does a woodworker NEED a laser? And, if not, can a woodworker find any use for one?

The answer to the first question is an obvious no, you don’t NEED a laser. But, the answer to the second question is a bit more nuanced.

The laser’s best work seems to be as a small project tool. You’ve probably seen the wooden “puzzles” made of thin balsa wood with tabs and slots. I’ve seen all kinds of different ideas like marble climbers, vehicles, musical instruments, or ships. Those are all cut out with laser engravers.

There are an infinite number of ideas like this that can be realized if you just create the design. You can also cut and engrave all sorts of different materials. It’s the small scale of the projects and working with different materials that gives the laser a reputation for being a somewhat novel, general maker tool.

But, to me, the biggest advantage a laser gives to the traditional woodworker making projects like furniture, cutting boards, and jewelry boxes, is custom engraving and cutting out letters.

I can customize every cutting board I make, from now on. I can put my logo into the apron of a table or add a family’s name into one of the planks in a table top before glue-up, fill it up with dark epoxy, and sand it flush. I can cut out just about any style of letter and build various wooden backgrounds to create a sign.

I see a laser as an automated scroll saw or carving chisel to a woodworker. Maybe you see that as a bad thing, that’s completely up to you, but I don’t see it any differently than using a table saw instead of a hand saw, or a thickness planer instead of a hand plane.

If you enjoy hand carving, hand sawing, or hand planing, go for it.

But, if you mainly find joy in the end product and doing it quickly and efficiently, or you don’t have the time to learn how to properly use hand tools, machines can be very helpful and efficient.

The Projects I Built

I want to show you the three different projects I whipped up without much thought over the last few days. There was a learning curve to get the proper settings for a solid burn, but other than that it was straight forward.

I used the Lightburn software with the Laser Master 3. At the time of writing, it’s $60 for the license, but they offer a 30 day free trial. If you have a Mac, this is basically the software you’ll want to use. If you have a Windows machine, you can use Lightburn or the free LaserGRBL software.

The first project was to engrave some coated tumblers. I was pretty easily able to put a design together and the quality of these engravings was amazing. Not only is the laser plenty powerful enough to engrave tumblers, but I had to turn the power way down. As I got closer to a proper power setting the metal went from a darker, charred look to a shiny look.

Next was an idea I saw somewhere online. I took some images from the internet, outlined them, and then let Lightburn create a trace of the outline. Then, I “welded” the image to a frame in Lightburn to create each side as one piece.

The Laser Master 3 easily cut out the design from 1/8″ balsa wood and I glued them up to make a neat little lamp.

Lastly, I built a sign from walnut and letters that were cutout from the same 1/8″ balsa wood. There is a great opportunity for woodworkers offering products to create some original and attractive signs. I just used a basic piece of walnut, but I’ve seen woodworkers build some really unique wooden backgrounds to attach the letters to.

A laser engraver is just another tool. That’s it. You can’t build an entire project out of 4/4 lumber with it, but what tool really can?

If you’re looking to customize your furniture or smaller woodworking projects, especially projects you’re selling, a laser engraver could be a valuable tool in your shop.

Get My Free Download that lists the exact tools & materials you need to create amazing projects

Recommended Reading

Building DIY Spice Rack Shelves With Only a Jigsaw

Organize your cabinet with this easy beginner woodworking project. I built these spice rack shelves with only a Jigsaw and a few accessories.

The Ultimate Shop Multi-Cabinet

This is the one shop organization cabinet to rule them all. It organizes six different tools and accessories into one incredible cabinet.

How to Make a Mudroom Cabinet Bench

This project was an interesting request from a local client. They needed some benches that would help accommodate their large team meetings.