I’m working on an extremely involved project right now that will be a centerpiece in our home for decades. It’s likely to be an heirloom piece passed down through the generations. And, I ran into a decision that threatened to affect the structural integrity of the table….

While cutting the tenons for the aprons I had to calculate the length and thickness of those tenons. And, the “rules” didn’t sound reasonable to me.

They go something like this:

- Tenon Length

- 1 rule says it should be 5 times the thickness of the tenon

- Another rule says 1/2 to 2/3 the thickness of the mortised piece

- Tenon Thickness

- 1/3 the thickness of the tenoned workpiece

- Another rule says 1/3 the thickness of the mortised workpiece

- Tenon Width

- Should be 1/2 the width of the tenoned workpiece

- If the width is 6 times its thickness, it should be split into 2 tenons

So, how do we make sense of this stuff? First, take these “rules” as guidelines and not requirements.

Tenon Length

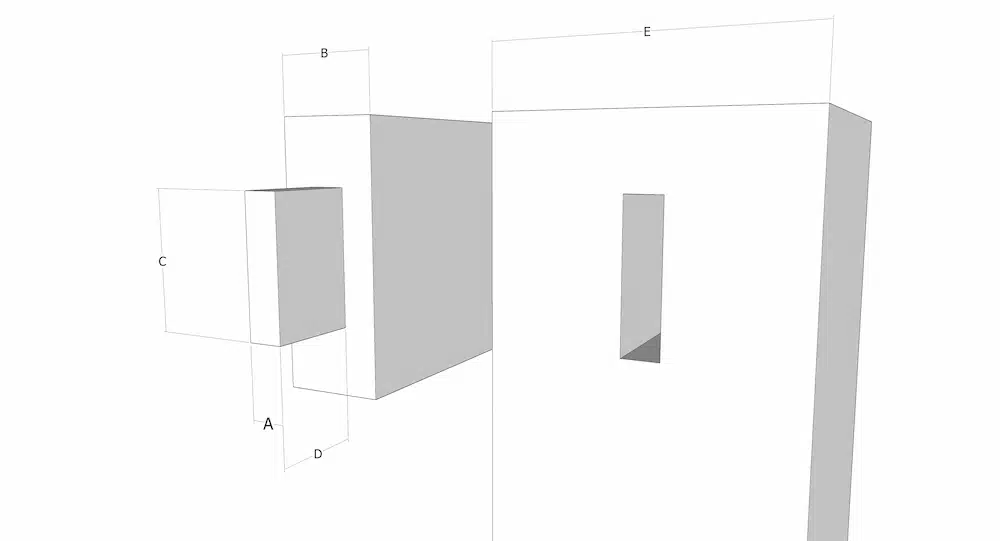

In the image above D represents the length of the tenon. One conventional rule says that this length should be 5 times the thickness (A). In my mind this is a silly rule and only applies if A is around 1/4″ or otherwise thin.

The game table I’m building above has 7/8″ aprons and 3″ legs. With a 1/2″ thick tenon, if I followed this rule, it would need to be a 2 1/2″ long tenon. While that would work for this 3″ leg, it won’t work with 2 tenons meeting in one leg.

2 1/2″ isn’t wrong, but I think it’s a little overkill. My solution was to make the longer front and back aprons with 1 1/2″ long tenons (D) and keep the end aprons with 1″ long tenons. I could have made the tenons on the front and back aprons longer, but I just don’t see the need.

Essentially, I ended up using the second rule that I see, occasionally, and made it half the thickness of the mortised workpiece (F). In this case, that was the 3″ leg.

Tenon Thickness

Just like everything else in life different rules are told different ways. I’ve seen at least two different guidelines for sizing the thickness (A) of a tenon. 1/3 the thickness of the tenoned piece or 1/3 the thickness of the mortised piece (F).

I think it’s easier to just go by the thickness of the tenoned piece (B) since the mortised piece can vary so wildly. In the case of the game table, the leg is so much thicker than the apron that it isn’t practical to size according to that.

Using 1/3 the thickness of the tenoned piece ensures your mortise walls unless you have a mortised piece that is thinner than the tenoned piece, for some reason.

Tenon Width

Width is also pretty straight-forward when it comes to sizing a tenon. Taking wood movement into account, you want the width of your tenon (C) to be about 1/2 – 2/3 the width of the tenoned workpiece (E).

The rule is that if I have a 1/4″ thick tenon (A), it can’t be over 1 1/2″ wide (C). That’s a width not more than 6 times its thickness. If it is wider than 6 times its thickness, you’ll need to separate it into 2 tenons.

The reason for this guideline is that you’re glueing the tenon to the mortise, crossgrain. The tenon will expand and contract across the width of the tenon, but you’re locking it in place with wood glue. But, as long as the tenon isn’t too wide, it won’t cause problems.

Final Thoughts

“Rules are made to be broken”, is how the old saying goes. But, rules are also there for a reason. Just use common sense and take these “rules” for what they are: guidelines to prevent badly built projects.

Get My Free Download that lists the exact tools & materials you need to create amazing projects

Recommended Reading

How to Remove Ink Stains From Wood Without Destroying It

I test 7 products on an ink stain in my new wooden desk. Some worked, some didn't, and one destroyed my desk.

I’m a Messy Woodworker Who Screws Up Constantly – 5 Things That Help

It’s true. I can’t use a tape measure without making a mess. And, I make mistakes. I don’t screw up near as much as I used to, but I have been known to rebuild entire portions of a project.

How To Cut a Bevel Greater Than 45 Degrees

This is an easy jig to accurately, safely, and reliably cut a bevel greater than 45 degrees on a large workpiece.